1

/

of

1

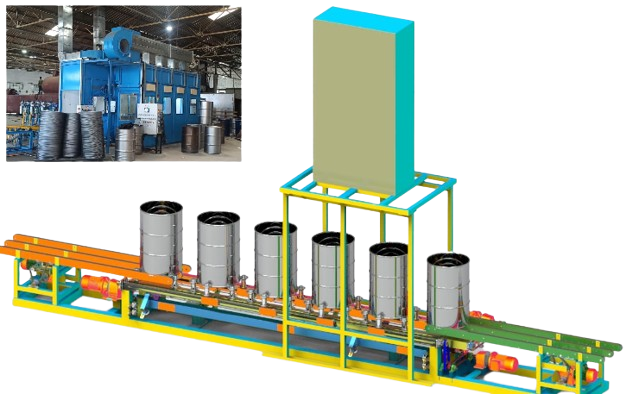

200L drum coating systems

200L drum coating systems

Regular price

€10.000,00 EUR

Regular price

Sale price

€10.000,00 EUR

Unit price

/

per

Taxes included.

Couldn't load pickup availability

A 200L drum coating system is an advanced automated or manual solution designed for the efficient application of protective coatings to 200-liter drums and barrels. These systems ensure high-quality finishes, improved coating adhesion, and optimized drying times, making them ideal for industrial packaging and hazardous material storage.

Features

-

Uniform & high-quality coating:

- Ensures a uniform 360-degree coating on drum surfaces

- Offers high-gloss, semi-gloss or matte finishes

- Compatible with a wide range of coatings, including primers, enamels and powder coatings

-

High efficiency & speed:

- Fully automated and manual operating options available

- High-speed application for mass production

- Rotary and conveyor systems for continuous processing

-

Corrosion resistance & durability:

- Increases resistance to rust, chemicals and environmental influences

- Extends drum life for long-term storage solutions

- Meets industry standards such as ISO and ASTM

-

Versatile application:

- Suitable for metal, plastic and fiber containers

- Works with solvent-based, water-based and powder coatings

- Adjustable coating thickness for individual protection needs

-

Cost-effective & environmentally friendly:

- Optimized ink transfer efficiency to minimize waste

- Low VOC solutions for environmentally friendly coatings

- Energy-efficient drying and curing systems to reduce operating costs

Our 200L drum coating systems include:

- Automatic drum spray booths: Ensure precise and even application

- Airless & Electrostatic Spray Systems: Improving Coating Transfer Efficiency

- Rotary & Conveyor Belt Coating Systems: Optimized for High-Speed Production

- Individual paint circulation and filtration systems: Ensuring consistent coating quality

- Infrared & UV drying systems: Improve drying speed and efficiency

Share